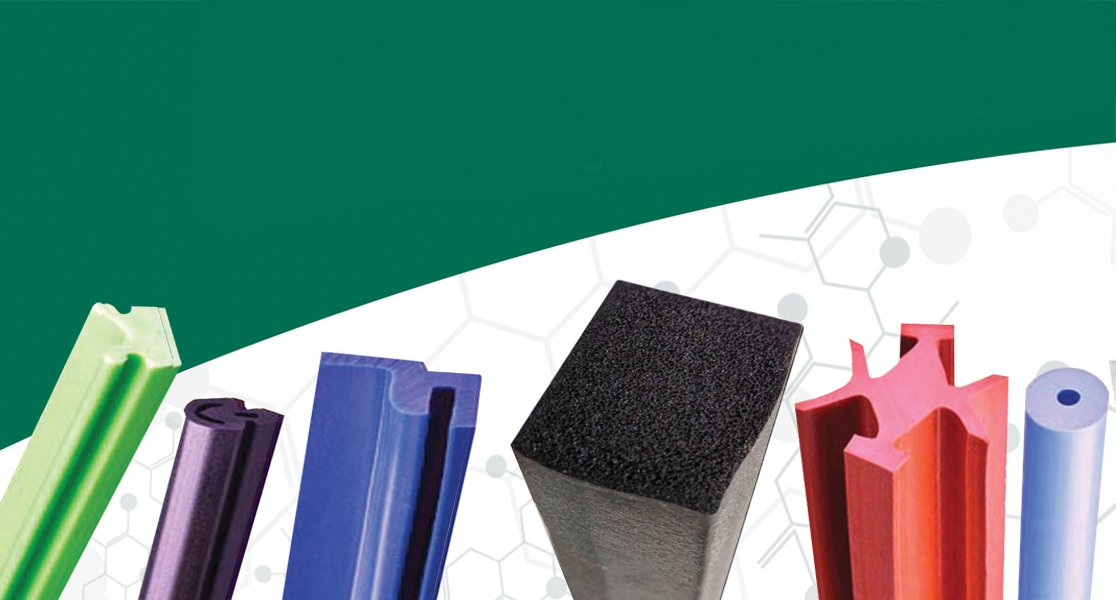

KNOW THE NEW EPDM BASE TECHNOLOGY FOR PRODUCTION OF SOLID OR SPONGY PROFILES

– Better permanent deformation (less than 25%) and better mechanical properties (tear, abrasion, resilience)

– Less specific weight (around 1 g / cm3 (the typical compounds being around 1,30 g / cm3 and 1,50 g / cm3

– Higher productivity (30% to 50%)

– Process in the same equipment used for elastomers, without the need for changes and adaptations

– Can be colored (any color)

-Possibility of creating spongy profiles, with an apparent density of up to 0.2g / cm3 “